The gear puller, a staple tool in both automotive and industrial repair, emerged during a transformative period in mechanical engineering—the late 19th and early 20th centuries. This seemingly simple tool, designed to remove gears, pulleys, and bearings from shafts and axles, was an essential innovation that addressed one of the most challenging tasks in mechanics: removing components without causing damage to the machinery.

The Origins of the Gear Puller

Before the invention of the gear puller, mechanics faced significant challenges when attempting to remove gears and bearings from their mounts. These parts, tightly fitted onto shafts and axles, could be incredibly difficult to extract without the risk of damaging the component or the surrounding equipment. Tools of the time were not equipped for this task, often leading to broken parts, bent axles, or unnecessary repairs.

It wasn’t until the late 1800s and early 1900s that the first gear pullers appeared on the scene. The gear puller was designed with precision in mind, allowing mechanics to apply a controlled pulling force to remove gears and bearings. This revolutionary tool made the process not only easier but safer for both the mechanic and the machinery.

How the Gear Puller Works

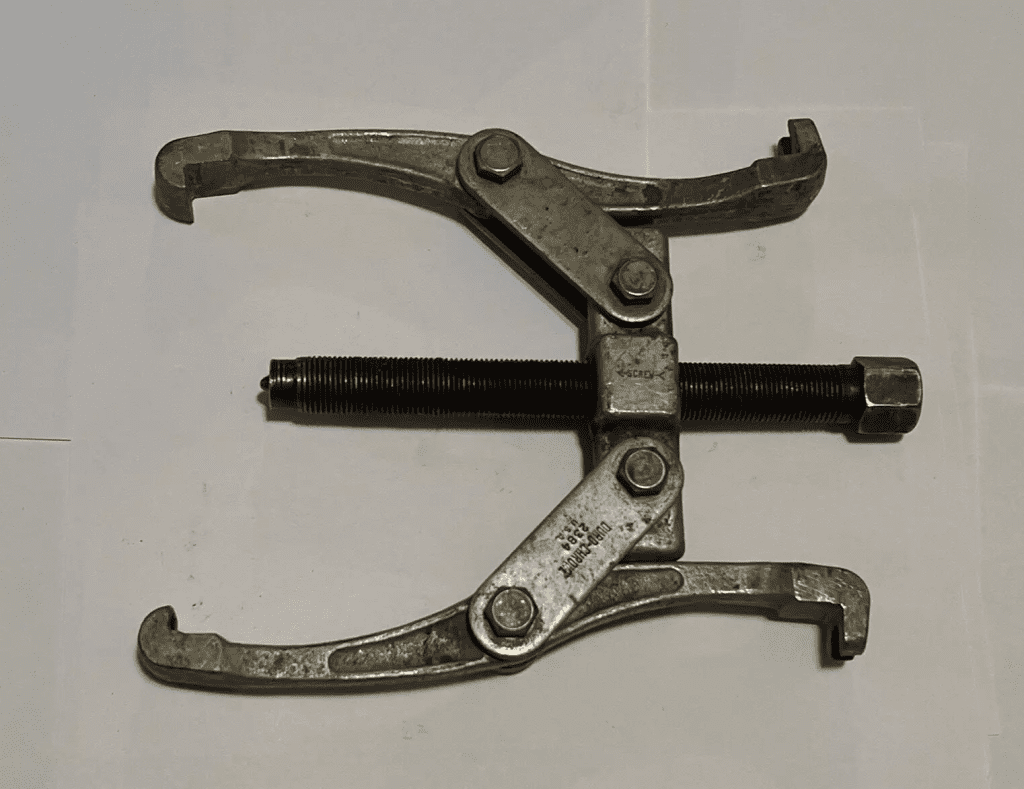

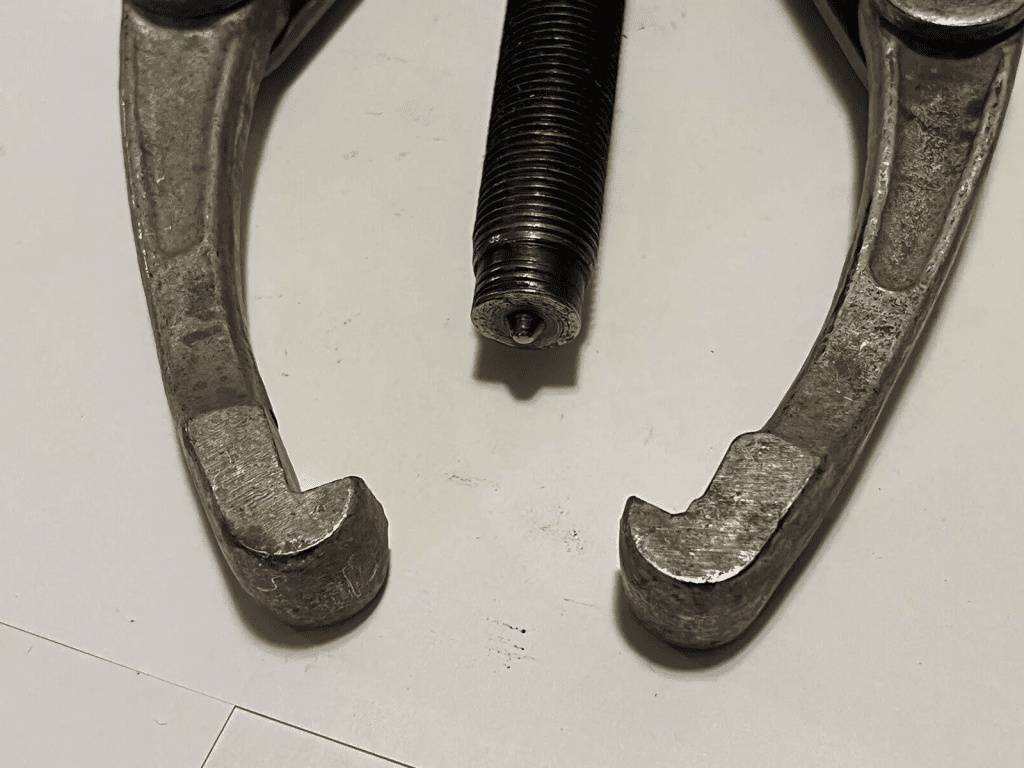

The fundamental design of a gear puller is simple but effective. It consists of a central screw and two or three adjustable arms that can be positioned around the gear, pulley, or bearing. Here’s how it works:

- The mechanic places the arms of the gear puller around the component they need to remove.

- The central screw is then tightened, applying a controlled, even force that pulls the gear or bearing away from the shaft.

- As the screw is turned, it pushes against the center of the shaft, allowing the arms to pull the component outward.

This design minimizes the risk of damaging either the part being removed or the shaft, making it ideal for precision work. Early gear pullers were typically manually operated, requiring mechanics to exert force by turning the central screw by hand. Despite the manual effort, these tools were highly effective, and their precision became indispensable in repair shops.

The Evolution of the Gear Puller

As mechanical technology advanced, so too did the design of the gear puller. In the early days, gear pullers were entirely manual and made of robust materials like cast iron or steel. These early tools were known for their durability and reliability, and many vintage gear pullers are still functional today, prized by collectors for their craftsmanship.

However, as machinery became more complex and demands for faster repair times increased, gear pullers evolved. By the mid-20th century, hydraulic and pneumatic gear pullers were introduced, offering greater pulling power and efficiency. Hydraulic gear pullers, for example, use pressurized fluid to apply the pulling force, which can be significantly more powerful than the force generated by a manual screw.

These technological advancements didn’t diminish the importance of the original gear puller design; rather, they enhanced its capabilities. Modern gear pullers can now handle larger, more intricate components, yet the fundamental principle remains the same—a controlled force applied to remove a component without damage.

Vintage Gear Pullers: A Symbol of Craftsmanship

Even with the rise of hydraulic and pneumatic tools, vintage gear pullers continue to hold a special place in the hearts of collectors, mechanics, and engineers. These tools represent a time when manual labor and precision craftsmanship were paramount in mechanical work.

Vintage gear pullers are admired for their:

- Durability: Built from high-quality materials, many vintage gear pullers are still functional today.

- Ingenuity: The simplicity and effectiveness of their design reflect a deep understanding of mechanical principles.

- Historical Value: They symbolize the progress of mechanical engineering, bridging the gap between early repair methods and modern technology.

Some collectors and enthusiasts actively seek out vintage gear pullers to showcase in museums or personal collections. These tools are often seen as works of art, meticulously crafted with the same attention to detail that defined early industrial tools.

The Gear Puller’s Impact on Mechanical Repair

The gear puller’s invention marked a significant shift in how mechanics approached repair and maintenance. Prior to its development, removing a stuck gear or bearing could involve brute force and risk of damage to critical components. The precision of the gear puller allowed for faster, safer, and more efficient repairs, which in turn improved the longevity of machinery.

In automotive and industrial settings, gear pullers became essential for a wide range of tasks, including:

- Removing gears from car engines during repairs or replacements.

- Extracting pulleys from motors or pumps.

- Taking out bearings without damaging the surrounding equipment.

The tool also significantly reduced downtime in industrial environments, as mechanics could quickly and efficiently complete repairs without worrying about damaging parts that could delay production.

The Legacy of the Gear Puller

The gear puller’s legacy is one of innovation, precision, and efficiency. While modern gear pullers have evolved to include advanced technology, the basic concept remains rooted in the original design from the late 19th century. The gear puller’s ability to remove components without damaging them has made it a staple in mechanical repair shops across the world.

Today, gear pullers are still a go-to tool for many mechanics and hobbyists, whether they’re working on vintage cars or modern machinery. The continued appreciation for vintage gear pullers, with their rich history and craftsmanship, reflects the lasting impact of these early tools on the industry.

Conclusion: The Enduring Importance of the Gear Puller

The history of the gear puller is a testament to the power of innovation in mechanical engineering. From its early days as a manual tool in the hands of mechanics in the late 19th century, to the advanced hydraulic systems used today, the gear puller has remained a fundamental part of repair and maintenance.

Its ability to remove components without causing damage revolutionized the way repairs were done, ensuring machinery could last longer and function more efficiently. And while modern technology has enhanced its capabilities, the basic design and function of the gear puller continue to be appreciated for their simplicity and effectiveness.

Whether you’re a mechanic, a collector, or simply a fan of mechanical ingenuity, the gear puller stands as an enduring symbol of the craftsmanship and innovation that shaped the world of engineering.